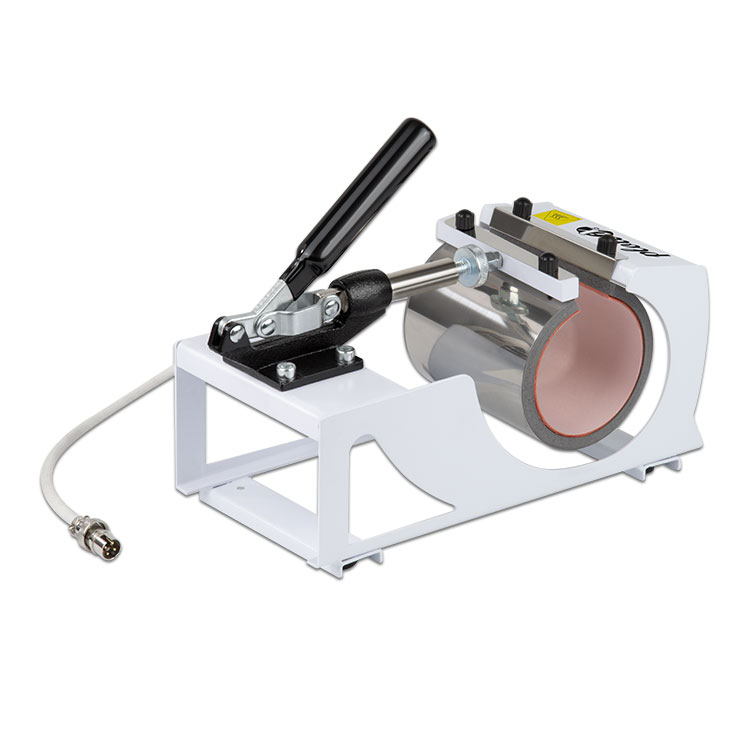

iXpress Mini 2 Transferpresse

The iXpress Mini is a small heat press which is ideal for pressing on small designs. Especially on corners, between buttons, seams, it can be easily used to achieve optimal results. Small areas like stuffed animals, baby shoes or hats can be decorated with the iXpress Mini.

The iXpress Mini is compatible with our plottiX iron-on foils and sublimation material.

- Easy application of iron-on films & sublimation designs

- Ideal for small projects

- Easy to use

- Space saving and quickly stowed away

- 6 x 10 cm pressing area

- 205°C maximum temperature